Fire Detection & Alarm Systems

Detection of Combustion Products and Incident Management

Detection – Warning – Evacuation

Fire Detection and Alarm System Types

Fires pose great risks for both life and property safety. To minimize these risks, fire detection systems play a vital role. With their critical importance in early warning and fire prevention, fire detection systems play a key role in preventing possible disasters and protecting life safety.

Other Solutions

Industrial Fire Detection and Alarm Solutions in Risky Areas

Gas Detectors

Gas Detection Solutions

Detection of accumulation of hazardous gases, detection of point leaks and leaks.

Fixed Point Gas Detectors

This type of detectors are positioned in the field according to the extent of the danger, environmental conditions and regulations. They detect toxic, flammable, flammable and explosive gas mixtures reaching the device at the point where they are positioned and provide information to the system.

Detection of Flame Rays

Flame Detectors

Special solutions that provide rapid detection of flames occurring at high-risk points.

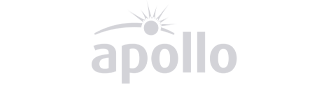

Sensitive Volumes 24/7 Smoke Detection

Air Sampling Fire detection

When it comes to smoke detection, air sampling fire detection systems, which can make the earliest and error-free detection, are more effective than other alternatives. In these systems, air suction and airborne particles are continuously measured from the protected volume. A possible smoke release is thus quickly detected by the panel.

Air sampling smoke detection system has a wide range of usage in small, medium and large volumes. Main areas of use;

Detection of Fire Heat

Cable Type Heat Detectors

Determination of the heat factor included in the fire equation cannot be achieved with point detectors in some areas. Developed for use in difficult areas and industry, cable type heat detectors transmit a fire alarm to the central system when they detect a predetermined temperature value in the area or equipment they protect.

It has 4 options: fixed, digital, analog and fiber optic. The main areas of use of cable type heat detectors are as follows:

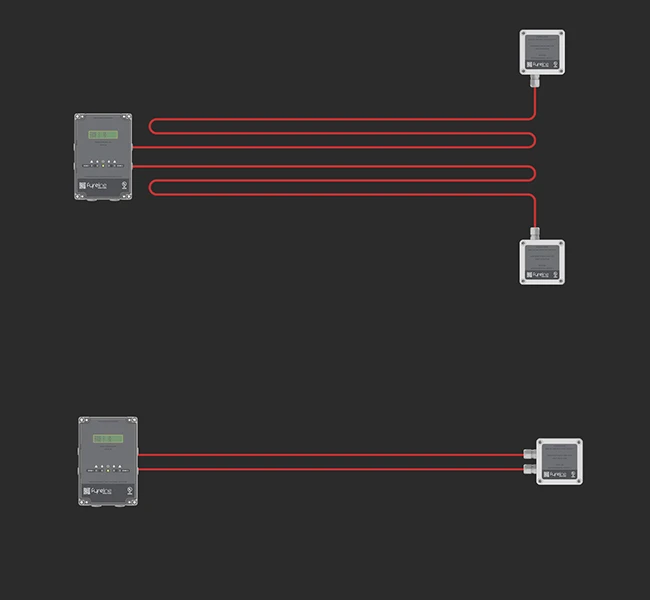

Detection and Extinguishing in Milliseconds

Spark Detection System

In situations where a fire is expected to trigger a major explosion, a rapid detection and extinguishing system is needed. Spark fire detection systems specially developed for this need to detect sparks created by small particles within milliseconds and activate the extinguishing system. In this way, the occurrence of large fires and explosions due to pressure increase are prevented.

The main areas of use of these systems, which have gone through special testing and approval processes, are as follows:

Fire Safety & Building Technologies

For detailed information

Contact us

We are here to answer all your questions about systems, product certificates, regulations, application and post-installation operating procedures.

Our Phone Numbers:

+90 232 111 22 33 (TR)

+99 897 036 15 84 (EN)