Water Based Extinguishing Systems

The Most Basic Automatic Protection Solution for Fire Fighting

Control Feature

Sprinkler systems save time for emergency responders by essentially limiting the fire.

Extinguishing Feature

Fires that start can be extinguished without support by using only some special sprinkler heads.

Simple – Effective – Reliable

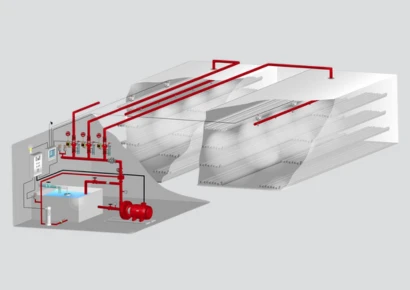

Water Fire Extinguishing System Methods

Fully automatic water extinguishing systems, which arise due to the inadequacy of human-used equipment in firefighting, are used to minimize damage caused by fire incidents in buildings.

Featured Benefits:

Protection Methods

Fully Automatic Water Extinguishing System Types

There are four different application techniques against environmental conditions, regulations and possible risks in the business.

Sprinkler Heads

Fire Sprinklers

A wide range of sprinklers and nozzles with different materials and mechanisms can meet every need.

Standard Sprinkler

These caps, which are generally used in low and medium risk areas, have an average protection area and small orifices. There are options with vertical, horizontal and vertical reflectors.

Warehouse Sprinkler

They are used to control or extinguish fire in areas with high fire load. ELO, CMDA, CMSA, and ESFR sprinklers are included in this group.

Spray Nozzle

These open-ended products are generally preferred for cooling a tank surface or creating a water curtain between the fire volume and another volume.

Residential & Commercial Building Sprinklers

These sprinkler heads, which have a wide range of color and throw distance options, can be supplied with custom-colored caps. Concealed type, horizontal type extended protection sprinklers are used in this class.

Dry Type Sprinkler

If sprinkler heads maintain a cold volume in wet pipe fire extinguishing systems, dry type sprinklers containing air are used to eliminate the risk of freezing.

Special Application sprinklers

There are hoods developed for use in corrosive environments, wooden roof areas and special industrial conditions. This sprinkler is preferred in environments with heavy working conditions.

Opening and Closing Valves

Cut-Off Valves

It is used to safely close and open the line in cases of maintenance, revision, malfunction and leakage.

Fire Installation Valves

Auxiliary Valves

Equipment used to protect and test fire installations and construct the sprinkler system.

Test Valves

Test valves produced for testing installed sprinkler systems without being activated by heat have an opening of the same value as the sprinkler orifice. The systems are checked while this valve is brought to the test opening. In maintenance mode, it ensures the discharge of water in the installation.

Fire Hydrant & Cabinets

Manual Equipment

Complementary products used in response to small fires and for emergency response teams.

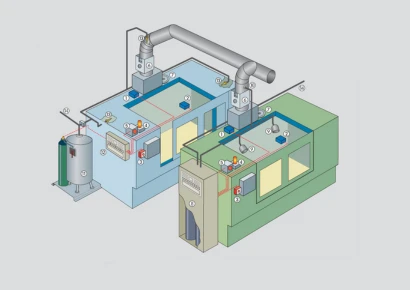

Deluge & Pre-Action Systems

Fire Detection System

Fire Detection Panel

The deluge alarm valve is triggered via a conventional panel.

Detectors

A or verification line is used using smoke, heat or flame detectors.

Warning and Alarm Devices

Sirens and flashers are used inside and outside to evacuate the volume before extinguishing.

Supervisory Connections

The central detection system remotely monitors error and alarm information on the extinguishing panel.

Preventing Water Damage in Sensitive Volumes

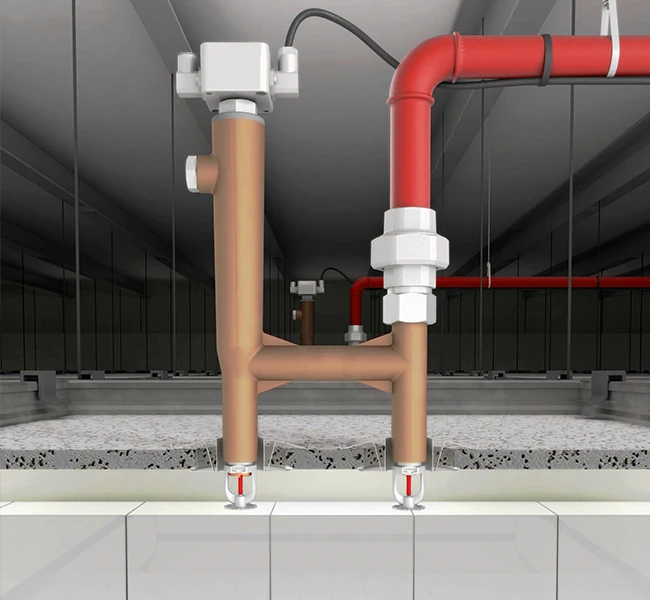

Pre Action

Sprinkler Head

It is produced to prevent water from being sent erroneously to the environment in volumes such as server rooms containing sensitive equipment. This sprinkler equipment consists of two separate heads. When activated by heat in two heads, extinguishing water is released into the environment.

Main Application Areas:

Special Industrial ApplicationsSpecial Industrial Applications

Explosion Protection & Cooling

Transformer Protection Systems

These systems, used to protect oiled and oil-free transformers, are an effective method to prevent possible transformer fires and explosions. In this system with a deluge valve applied at high pressure and flow rate, the design and application are made according to standards such as NFPA 15 and 13. When transformers are also secured with fire walls and drainage systems, the risk for businesses is minimized.

The system equipment used is as follows:

New Technology in Water Extinguishing

Water Mist Fire Extinguishing Systems

Compared to classical water extinguishing systems, these systems, which separate water from smaller particles with special spray heads, have started a new era in firefighting. Water mist fire extinguishing systems, developed as an alternative to classical sprinkler systems, are rapidly becoming more widespread and their usage areas are expanding day by day. The basis of the system is to pulverize water particles and turn them into very small diameter water particles. Thus, the same amount of water has a higher surface area and absorbs the heat in the environment more efficiently. The water that turns into fog evaporates around the burning surface and forms a barrier. In this way, the contact of the burning surface with oxygen is interrupted and three-dimensional protection is provided.

Water Mist System Types:

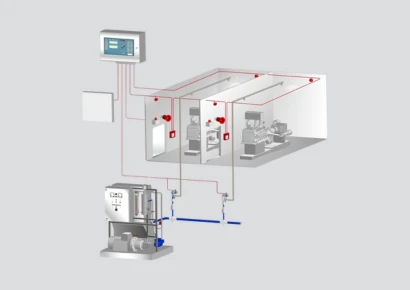

Installed System Images

Water Based Fire Protection

Application Examples

Fire Safety & Building Technologies

For detailed information

Contact us

We are here to answer all your questions about systems, product certificates, regulations, application and post-installation operating procedures.

Our Phone Numbers:

+90 232 111 22 33 (TR)

+99 897 036 15 84 (EN)